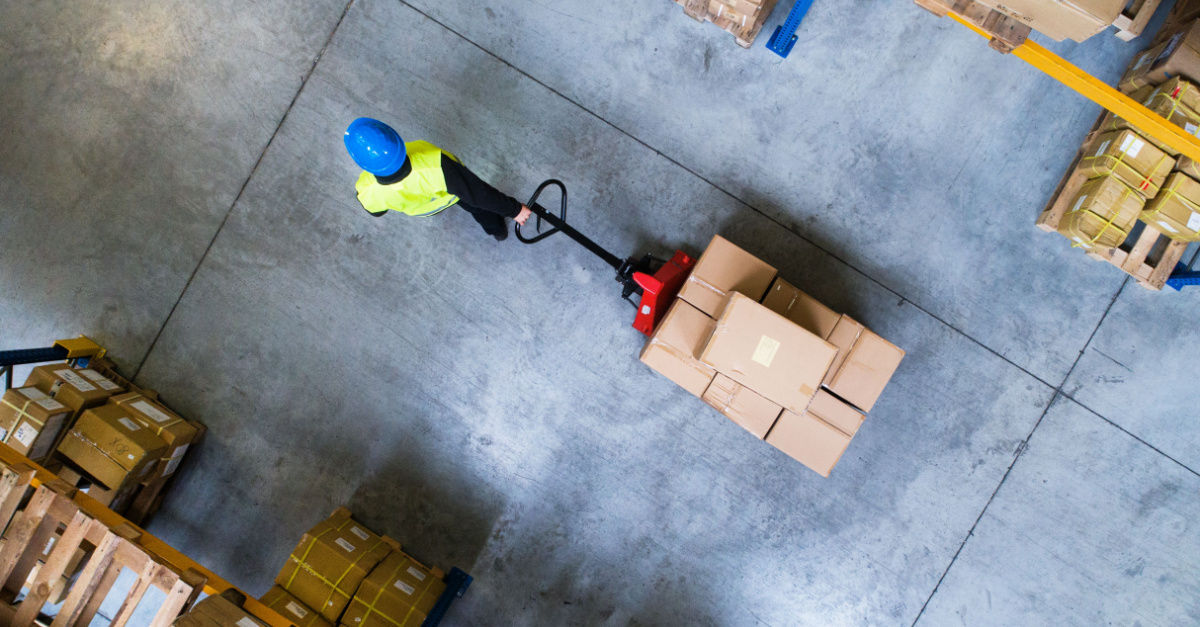

A manufacturer’s inventory is its lifeblood, the basic ingredients for whatever is being made. When it comes to storing materials in the warehouse, there has to be enough materials on hand at all times, and they have to be in good condition. If these requirements aren’t fully met, a factory could shut down. Therefore, managing inventory in the warehouse well is incredibly important.

Warehouse inventory management is part and parcel of inventory management. Both involve overseeing and controlling stock and its levels, but whereas inventory management concerns the entire supply chain from ordering to delivering, warehouse management is about just the inventory in the warehouse. Let’s look at eight practices for streamlining inventory management in a warehouse.

The overall design of the storage facility is a critically important factor. The layout will determine how staff and machinery maneuver the space, as well as how items are placed in, and removed from, storage. When the floor plan is a good one, inventory can be moved in, out, and around the area in a simple, free-flowing stream; when that isn’t the case, bottlenecks and errors can occur.

There are three basic designs for warehouse layouts:

These three floor plans have come to be recognized as the ones that work best for warehouse design over time. This isn’t just because they’re good for flow; however, the efficiency they create is reflected in the bottom line.

What we’re addressing here is the frequency with which items are needed, and using that measure to gauge where best to place them. You have:

For the most efficient placement, fast-moving products should be placed near the front and be as easy to get to as possible, while those used but less in demand can be further back. High racks and difficult-to-access areas can be reserved for those non-moving items.

Knowing exactly what you have in storage is the core of good warehouse inventory management. While it’s relatively easy for small companies to keep on top of this, it becomes increasingly difficult for businesses as they grow. For them, technology is a necessity.

Inventory management systems (IMS) use barcodes and QR codes to track inventory. QR codes can hold much more information than barcodes. In addition to storing information about a product, QR codes know exactly where each item is stored, so they are much better for larger facilities. An inventory management software like Cin7 Omni, can maintain an accurate record of warehouse stock, letting you know exactly what’s there and tracking it as it moves in and out the storage area. This is the kind of information you need to manage the inventory on a daily basis.

The importance of the warehouse manager cannot be overstated. They don’t only oversee the pool of staff that works in the warehouse, they’re in charge of the inventory itself, making decisions every day about where to store it and when to move it. If they don’t do this in the most efficient way possible, goods can be damaged and extra costs can be incurred.

Warehouse managers should be tech-savvy. They need to be able to operate the software and handle all the automation and machinery that moves the inventory around from robots to forklifts.

The workflow in a warehouse starts the instant inventory is brought into the building and ends the moment it leaves. It covers all the processes involved in moving the items around, including administration. Individually, warehouse workflows depend on the design of the facility, the product, and frequency of its use. Warehouse flow is usually the province of the warehouse manager. He or she will make the decisions about how and where inventory is stored and when any of it should be moved.

A well-thought-out plan will ensure unheeded flow of the inventory and make the best use of workers’ time. Like any business plan, though, workflows should be revisited often so that updates and tweaks can be made in response to any changes.

We’ve already discussed the benefits of using inventory management software to keep tabs on stock that’s in the warehouse and know at all times exactly what’s in storage. But these IMS systems can actually do much more. They can:

As mentioned, Cin7 Omni is a good way to automate. As a complement to the functions listed here, the software will increase the speed, accuracy, and security of the inventory management process. It also reduces the employee workload, including that of the warehouse manager, leaving them free to take on other tasks.

Theft, unfortunately, is a fact of life, and the possibility of it happening has to be taken into account when discussing inventory management in the warehouse. One way to stop theft is by putting up closed-circuit surveillance cameras and security systems like alarms. Letting only essential workers into the warehouse space and having them sign in and out when they report for work and go home can also be a help with this problem.

Even when the inventory in your warehouse is automated, audits are necessary. In addition to checking to see that the information in your financial records tallies with the records you’re keeping on your storage space, audits are a great way to point out items you don’t need to keep any longer. These could include items that have been there for so long, they’ve gone out of style and can’t be used, or, for food, have passed their expiration dates. Apropos of #7, theft, an audit will also throw into sharp relief goods that may have “walked.”

A critical factor in warehouse inventory management, audits can be carried out internally by a member of management or externally by an outside agency. Either way, when conducted regularly they ensure that the records kept on inventory are as accurate as possible, and that, in and of itself, is a major cost saving for the company.

The way inventory is managed in the warehouse has repercussions both for the efficient handling and tracking of the stock and the bottom line of the company. We’ve laid out eight aspects of inventory management and have suggested measures that can be put in place to get the system working at its best. Hopefully, you’ll find them helpful in streamlining your system.

We think you’ll find Cin7 Omni a good tool to achieve this. To find out more about how the software can improve inventory management in your warehouse, click here to book a demo.

There’s more to running a warehouse than just piling inventory on shelves. The design of your warehouse can make or break your overall operational efficiency. Warehouse layouts need to be optimized for clear visibility, smooth transfer of goods, and easy equipment accessibility. And no one design will work for everyone. Most companies use one of […]

When managing a warehouse with thousands of products and having to determine and organize inventory, monitor delivery dates for incoming stock, and ensure the correct delivery schedule, human error is all but certain to occur. Thankfully, new technologies have emerged that are designed to specifically address warehouse management issues. With a comprehensive and an efficient […]

Warehouses can be hazardous. First, the items they hold are stacked high and close together to make the best use of space. Second, a lot of pickers and machinery are going back and forth between the aisles and up and down the storage bins all the time. If the items haven’t been stored properly, if […]